FILLING SYSTEMS FOR TOMATO SAUCES,

KETCHUP & SYRUPS

KETCHUP AND SAUCES: A SENSITIVE AND VARIABLE PRODUCTS

Ketchup and sauces mainly need a filler with hygienic design but at the same time flexible to be able to manage products with different characteristics (viscosity, tendency to foaming, filling temperature, contents of solids) on the same machine.

METALNOVA can handle these kind of products with traditional level filler with vacuum and recirculation or with new generation volumetric fillers based on magnetic flowmeters.

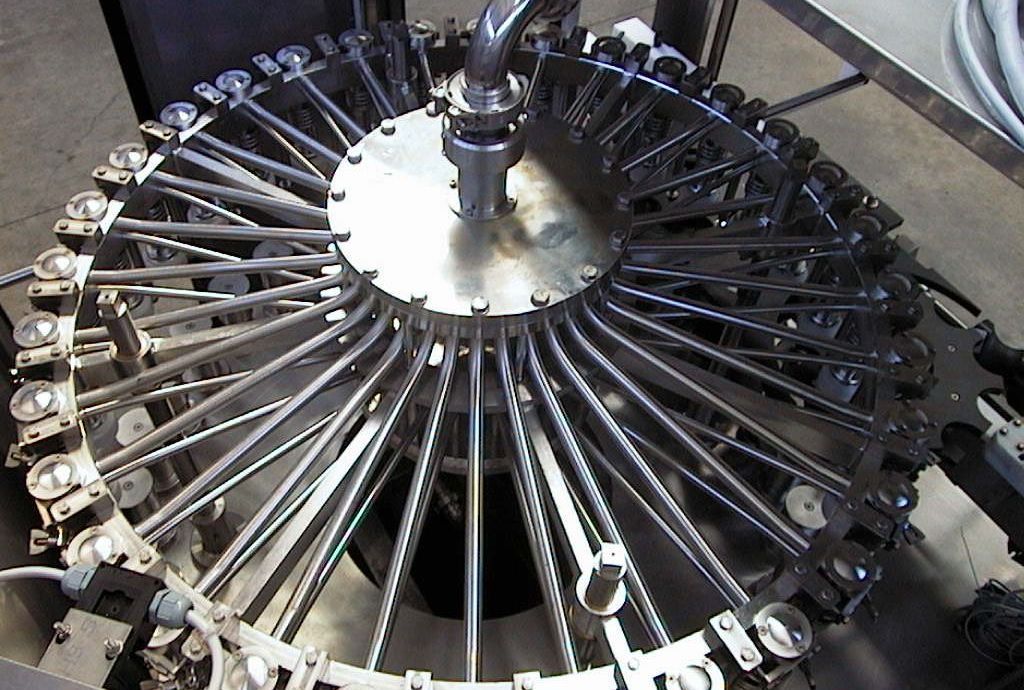

HVR

HIGH VACUUM LEVEL FILLING SYSTEM WITH RECIRCULATION

KEY FEATURES:

- Vacuum and recirculation to handle various viscosity and keep the machine at constant temperature

in case of hot filling. - External tanks to guarantee easy cleaning.

GENERAL FEATURES:

-

- Level filling system by low vacuum and recirculation.

- Recirculation filling valve, with membrane, without sliding parts in contact with the product.

- Filling valve opening realized by the bottle lifting.

- External tanks for product feeding and recirculation / vacuum generation.

- Upper product feeding tank with device for level control, product infeed valve, spray ball for cleaning.

- Lower tank with device for vacuum generation, recirculation pump, spray ball for cleaning, device for vacuum intensity adjustment.

- Manifold for the connection fixed pipe – rotating pipe with with special treatment in the sliding parts to guarantee longer life.

- Small dimension central manifold for product distribution to the filling valves and return to the lower tank.

- Parts in contact with the product in stainless steel AISI 304 (standard) or AISI 316 (on demand).

- Sealing rubber complying with food norms.

- Machine predisposed for hot CIP in recirculation (CIP group excluded); possibility of in and counter-flow.

- Dummy bottles with manual set up.

- Carousel frame manufactured in stainless steel AISI 304.

- Pneumatic bottle lifters with neck bracket for PET bottles or with bottom plate for glass bottles.

- Machine available in “neck handling” version (fixed height carrousel, typically used for PET bottles) or in “body handling” version (height adjustable carrousel, typically used for glass bottles).

FOR HOT FILLING

- Control temperature with PT100 probe in the lower tank to drive the electro valve on the delivery of the recirculation pump (temperature OK = recirculation to the upper tank, low temperature = return to the process).

- Three ways infeed valve to send back the product to process in case of machine slow down or stop.

- Small recirculation flow even during machine stop in order to maintain the machine temperature.

- Possibility to realize external tanks with thermal insulation or with double jacket execution for hot water circulation to reduce the product temperature drop.

OPTIONS:

- External Tanks insulation.

VMAG

ELECTRONIC VOLUMETRIC FILLING SYSTEM BASED ON MAGNETIC FLOWMETERS

THE MODERN SYSTEM TO FILL SAUCES, KETCHUP AND SYRUPS IN HYGENIC AND FLEXIBLE CONDITIONS

KEY FEATURES:

- Contactless filling to achieve high hygiene level.

- Low maintenance cost thanks to mechanical parts reduction.

GENERAL FEATURES:

- Filling valve opening by electro pneumatic valve.

- Double filling speed, to guarantee reduced filling time and to avoid product splash out.

- Volume set up for each filling valve in HMI touch screen.

- Parameters Memorization set for each bottle size, with the possibility to select them in operator HMI touch screen panel.

- External product feeding tank complete with level control, infeed valve, spray ball for cleaning, pump for product transfer to the filling valves.

- Machine available in “neck handling” version (fixed height carrousel and bottle support in the neck, typically used for PET bottles) or in “body handling” version (height adjustable carrousel and bottle support in the bottom, typically used for glass bottles or HDPE bottles).

OPTIONS:

- Automatic Dummy Bottles.

- Sterile Filter on product tank.

| HVR |

| The system guarantees a precise filling level |

| Bottle in contact with filling valve |

| Level adjustment thanks to level spacers |

| Pneumatic bottle lifters |

| Only manual dummy bottles available |

| VMAG |

| The system guarantees a volume |

| Contactless filling |

| Recipe Volume from HMI panel |

| No bottle lifter necessary |

| Automatic dummy bottles available |

Via Mercalli 4/A - 43122 Parma – ITALY

+39 0521 607568

info@mnmetalnova.it

WORKING HOURS

08:00 AM – 12:00 AM – 1:30 PM – 5.00 PM

CONTACT US