RIEMPITRICI E LINEE COMPLETE DI IMBOTTIGLIAMENTO

PER BEVANDE E PRODOTTI ALIMENTARI LIQUIDI

DAL 1981 AL SERVIZIO DEI CLIENTI

RICHIEDI SUBITO LA TUA OFFERTA COMMERCIALE!

I NOSTRI PRODOTTI E SERVIZI

IMBOTTIGLIARE SENZA LIMITI

Produciamo riempitrici per bevande come: acqua piatta e gassata, carbonated soft drinks CSD, succhi, sciroppi, latte fresco ed ESL, birra, aceto, liquori, vino. Riempiamo anche prodotti alimentari liquidi (olio alimentare, passate di pomodoro, salse e ketchup).

TECNOLOGIA BREVETTATA BASELESS

BASELESS è l’innovativo design Brevettato per macchine di imbottigliamento, con motorizzazione nella parte superiore della macchina per avere la zona al di sotto delle bottiglie completamente libera.

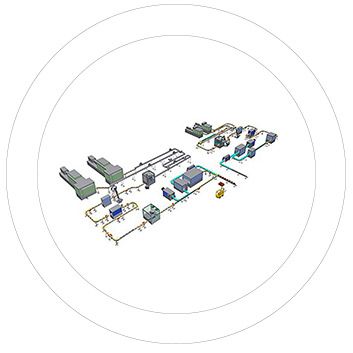

LINEE COMPLETE CHIAVI IN MANO

Progettiamo e produciamo nastri trasportatori per bottiglie vuote e piene, cartoni, fardelli e casse. Inoltre forniamo linee complete di imbottigliamento chiavi in mano integrando le macchine di nostra produzione con macchine di subfornitura di costruttori specializzati nei relativi settori.

I PRODOTTI CHE IMBOTTIGLIAMO

ACQUA PIATTA

Riempitrici idonee a riempire acqua, piatta

in bottiglie PET, R-PET, HDPE, PoliCarbonato, vetro e lattine,

ACQUA GASSATA

Le Nostre Riempitrici sono idonee a riempire acqua gassata

in contenitori di PET e R-PET e VETRO

BIBITE GASSATE - CSD

Le Riempitrici sono idonee a riempire acqua gassata e soft drinks CSD in bottiglie di PET, R-PET, vetro e lattine.

VINO FERMO

Le tradizionali Riempitrici idonee a riempire vino fermo

in bottiglie di VETRO e lattine.

VINO FRIZZANTE

Nuove Riempitrici idonee a riempire Vino frizzante, Alcopopos e vino e fermo in bottiglie di VETRO e lattine.

OLIO ALIMENTARE

Performanti Riempitrici idonee a riempire olio alimentare in bottiglie PET , r-PET, HDPE, PC e Latte con o senza maniglia ed in vetro.

LATTE FRESCO ED ESL

Innovative Riempitrici idonee a riempire Latte Fresco ed ESL, Leben, Laben, Ayran, Latte fermentato in bottiglie PET o vetro.

SALSE & PASSATE DI POMODORO

Tradizionali Riempitrici idonee a riempire salse,

passate di pomodoro e ketchup

SUCCHI & SCIROPPI

Imbottigliatrci idonee a riempire succhi, sciroppi e salse

in bottiglie PET, vetro e lattine con riempimento a caldo o a freddo.

LIQUORE

Le Nostre Riempitrici sono idonee a riempire liquori e vino

in PET e VETRO.

I CONTENITORI IN CUI IMBOTTIGLIAMO

VETRO

Riempitrici Isobariche e/o a gravità idonee a riempire bottiglie di vetro a caldo e/o a freddo

GRANDI FORMATI

Riempitrici Lineari o Rotative idonee a riempire grandi contenitori PET (da 3 a 20 lt) e POLICARBONATO

LATTINE

Riempitrici Rotative volumetriche idonee a riempire LATTINE in alluminio.

LATTE IN BANDA STAGNATA

Efficienti Riempitrici Lineari o Rotative idonee a riempire latte per olio ed altri prodotti con differenti tappi.

TANICHE IN HDPE

Riempitrici Rotative o Lineari idonee a riempire taniche in HDPE (da 3 a 20 lt).

Perchè sceglierci

Accuratezza dei dettagli

La nostra progettazione è concentrata sulla qualità del prodotto ed Hygienic Design

Flessibilità Tecnica

Miglioriamo continuamente le nostre macchine per proporre soluzioni all’avanguardia e affidabili per soddisfare le richieste dei Clienti

Vicini al Cliente

La struttura della nostra Azienda ci permette di essere vicini ai Clienti dal momento della vendita e per il resto della vita della macchina.

INSERISCI SUBITO LA TUA OFFERTA COMMERCIALE

Via Mercalli 4/A - 43122 Parma – ITALY

+39 0521 607568

info@mnmetalnova.it

WORKING HOURS

08:00 AM – 12:00 AM – 1:30 PM – 5.00 PM

CONTACT US